Given that the International Living Future Institute (ILFI) recently launched a new version of its Zero Carbon Certification (ZC), you may be wondering what this means for your projects. In this two-part series, we outline the changes to ILFI ZC 1.1 and share what developers, designers, and contractors can do to prepare.

Read Part 1 to see how embodied and operational carbon requirements have changed. Then, let’s dive into what you can do to set your projects up for success.

#1: PERFORM AN EARLY DESIGN ZERO CARBON FEASIBILITY STUDY

Performing a Zero Carbon feasibility study at schematic design (or even earlier!) helps project teams identify and understand:

-

- Project typology: interior, renovation, or new building; and associated zero carbon goals

- Probability of meeting embodied and operational carbon targets, and major opportunities for cost-effective decarbonization

- Material carbon hotspots, energy use hotspots, and reduction strategies

- All-electric design challenges and solutions

- Team responsibilities such as data collection and reporting processes

Operational Carbon:

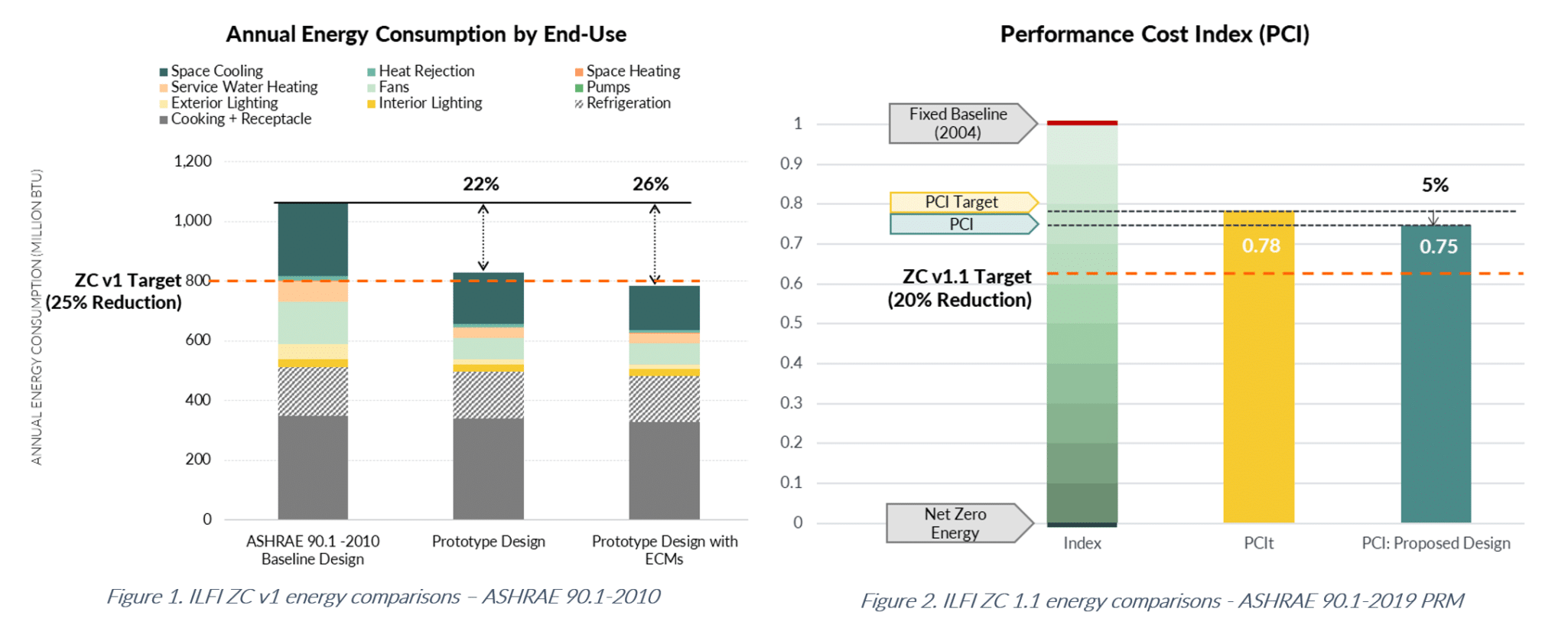

Meeting the updated operational carbon baseline (20% better than ASHRAE 90.1-2019) is a challenge. This is because (1) the U.S. Department of Energy (DOE) analysis finds that ASHRAE 90.1-2019 is more stringent by approximately 18% compared to the 2010 version and (2) this ASHRAE standard also uses a significantly revised calculation method for a project’s energy modeling pathway, which in our experience makes it more difficult to achieve 20%+ energy savings, as required by ZC 1.1. Therefore, an early phase feasibility study can be incredibly valuable.

Figure 1 shows the early-phase energy analysis for a restaurant project pursuing ILFI ZC v1. We collaborated with the client, architect, and engineers to apply energy conservation measures (ECMs) and successfully achieved the 25% reduction target (based on ASHRAE 90.1-2010). Figure 2 shows the same building compared to ASHRAE 90.1-2019 baseline for ILFI ZC 1.1. It shows a 5% reduction, which does not meet the 20% threshold for ILFI ZC 1.1 requirements. In this case, additional ECMs will need to be considered in the Zero Carbon feasibility study to be compliant with the new ZC 1.1 Standard.

Figure 1 shows the early-phase energy analysis for a restaurant project pursuing ILFI ZC v1. We collaborated with the client, architect, and engineers to apply energy conservation measures (ECMs) and successfully achieved the 25% reduction target (based on ASHRAE 90.1-2010). Figure 2 shows the same building compared to ASHRAE 90.1-2019 baseline for ILFI ZC 1.1. It shows a 5% reduction, which does not meet the 20% threshold for ILFI ZC 1.1 requirements. In this case, additional ECMs will need to be considered in the Zero Carbon feasibility study to be compliant with the new ZC 1.1 Standard.

Embodied Carbon:

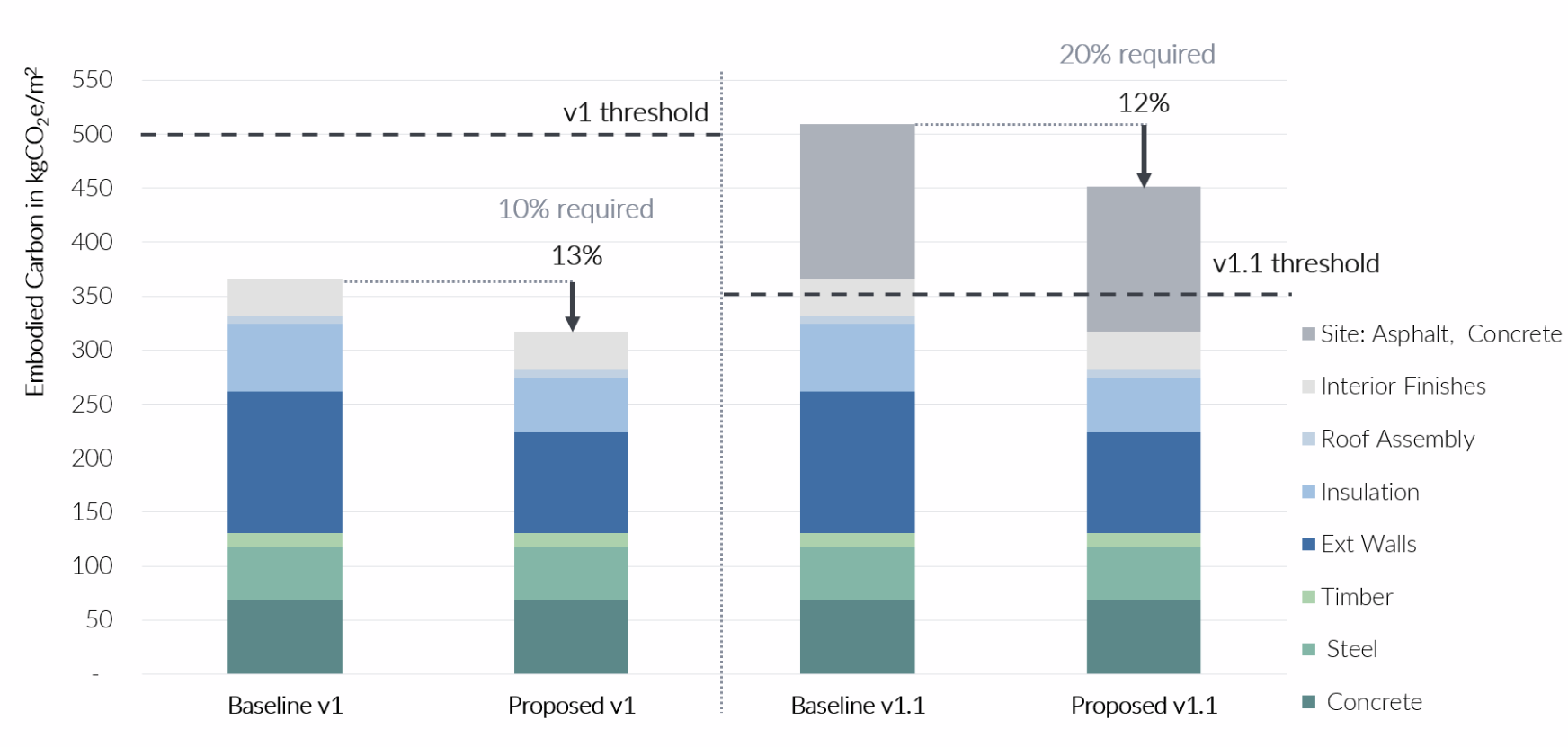

New embodied carbon thresholds and percentage reduction targets are equally difficult to achieve in ZC 1.1. An early design feasibility study can identify challenges and solutions, and can be used to create a decarbonization plan, as shown in the graph below that compares embodied carbon results of the same restaurant building with v1 and 1.1 requirements. Depending on the extent and materials used in sitework, the project’s embodied carbon can increase significantly, making it extremely challenging to meet these targets without taking drastic measures for sitework, such as significantly reducing parking area, or replacing asphalt with stabilized crushed stone. These and other solutions can be evaluated in an early Zero Carbon feasibility study.

#2: FIND SYNERGIES WITH LOCAL CODES, OTHER CERTIFICATIONS, AND CORPORATE COMMITMENTS

Operational Carbon:

All ILFI ZC 1.1 projects must offset 100% of the operational energy with new on- or off-site renewable energy; therefore, Zero Carbon certification is more stringent than most of the local code requirements and green building certifications, such as LEED. This means that by meeting ILFI ZC 1.1 requirements, many other green building energy efficiency standards or local energy codes will be met as well without any additional effort.

Renewable energy offsets aside, the updated ILFI ZC 1.1 has a more stringent energy efficiency requirement. The baseline standard of LEED v4.1 is ASHRAE 90.1-2016. The upcoming LEED v5 uses ASHRAE 90.1-2019 for projects registered prior to January 1, 2028, which aligns with ZC 1.1.

Embodied Carbon:

With most decarbonization initiatives starting to align with SBTi, developers are likely to find synergies in impact reduction efforts with local codes and their own corporate commitments. For instance, the City of Vancouver, BC will require an embodied carbon threshold of 400kgCO2e/m2 from 2025 for most buildings, which is very close to the ILFI 1.1 350 kgCO2e/m2 target. Check out CLF’s Embodied Carbon Policy Tracking Map for local code requirements. Some other certifications align with ILFI ZC 1.1 too, like LEED BD+C v4.1, which awards 4 points for 20% reduction in embodied carbon from baseline along with a few other criteria.

#3: USE A REDUCTION-FIRST APPROACH

The intent of the energy efficiency requirement for new construction is to achieve at least a 20% energy consumption reduction from ASHRAE 90.1-2019 or IECC 2021 without the inclusion of on- or off-site renewable energy. All projects must show energy reduction before accounting for on-site renewable energy.

Improving building energy efficiency by designing optimized envelope assemblies, selecting high-efficiency lighting fixtures with smart controls, and utilizing energy-efficient heating and cooling systems is the key to achieving the ILFI ZC target. Offsetting with photovoltaics (PV) alone won’t cut it.

Even better, select building materials and systems that will reduce both operational and embodied carbon over the life of the building. Each choice made to reduce operational carbon has an impact on embodied carbon, and vice versa. For example, the whole life carbon payback on adding 1” of XPS insulation is 11.4 years. A skilled decarbonization expert can help you make the best choices, holistically, for reduced carbon impact.

#4: SET CLEAR TEAM RESPONSIBILITIES FOR EMBODIED CARBON REDUCTION AND REPORTING

Architectural and structural design firms have started creating their own set of global warming potential (GWP) performance-based specifications and material palette that can aid in the 20% reduction requirement from baseline. With the addition of sitework in the embodied carbon scope, including landscape designers and civil engineers in embodied carbon discussions early on will set projects up for success, as concrete pavers, asphalt, and retaining walls have significant impact on a project’s embodied carbon.

Contractors now also play a larger role as ILFI ZC 1.1 requires projects to report emissions from site activities and material waste separately. Several contractors now have templates to track construction fuel logs and utility data, and are starting to identify strategies to reduce construction emissions. In another case of alignment, material waste tracking methods that have been in place for LEED can now be utilized for ILFI requirements.

READY TO DECARBONIZE NOW?

While ILFI LBC v4.1, ZE 1.1, and ZC 1.1 updates have been in effect since April, projects may register under the older versions until June 30, 2024 and submit their final documentation by end of 2029. That said, projects that plan to certify under ILFI Zero Carbon 1.1 can set themselves up for enhanced resilience and asset value under the version’s more stringent performance requirements.

Whatever path to zero you choose, Stok is here to guide you. Read our intro to ILFI Zero Carbon for a primer on the certification, review Part 1 of our guide to understand the latest changes, and reach out to discuss your project’s decarbonization goals and #DecarbonizeNow!