If you want to reduce your real estate’s carbon footprint, you should care about embodied carbon.

Whether you’re pursuing the ILFI’s recently-launched Zero Carbon Certification or creating your own framework, addressing embodied carbon (in tandem with operational carbon reduction strategies like electrification and carbon offsets) is a critical component of achieving true Net Zero Carbon goals.

Not sure where to start? Let’s walk through some frequently asked embodied carbon questions so you can begin to move your project toward true Net Zero Carbon.

HOW CAN I ADDRESS EMBODIED CARBON IN MY PROJECTS?

If your project is targeting Net Zero Carbon, embodied carbon reduction is likely a key component of your efforts in addition to operational carbon elimination. For the ILFI’s Zero Carbon Certification, this means a 10% reduction in embodied carbon, an overall embodied carbon efficiency under 46.5 kg-CO2e/ft2, and purchasing offsets for the project’s remaining embodied carbon.

To begin understanding the embodied carbon of your project, you should engage a consultant to perform a Life-Cycle Assessment (LCA): a technical analysis that assesses environmental impacts (including carbon emissions) associated with every stage of a building’s life cycle, including extraction, production, transportation, installation, and disposal of materials. The LCA results can then be used to optimize the project design, select low-impact materials, and reduce the overall carbon footprint.

WHAT TYPES OF PROJECTS CAN BENEFIT FROM EMBODIED CARBON ANALYSIS?

In short, pretty much all of ‘em! You can apply embodied carbon analysis to a wide array of building project types. Learn more about how to approach embodied carbon in these different scenarios:

Ground-Up/New Construction:

As a majority of embodied carbon is due to a building’s core and shell, performing an embodied carbon analysis on a new construction project is a no-brainer and thus most common. When you’re building from the ground up and making structural decisions, you have the greatest control over embodied carbon from the project’s outset, making getting to Net Zero Carbon much more feasible.

Tenant Interiors:

Though most of a project’s embodied carbon lives in core and shell materials, a tenant moving into an existing building can still make design decisions that significantly reduce their project’s overall carbon footprint. This is largely because interior products often have shorter life spans than structural systems, which are designed to last for the building’s life. For example, paint is typically intended to last 10 years, so it’s important to understand the embodied carbon impacts of painting 5 times over a 50-year building life (and in fact, likely more, as most tenants won’t wait a full 10 years to repaint). An LCA takes product life into consideration to drive design decisions.

Portfolio-Wide:

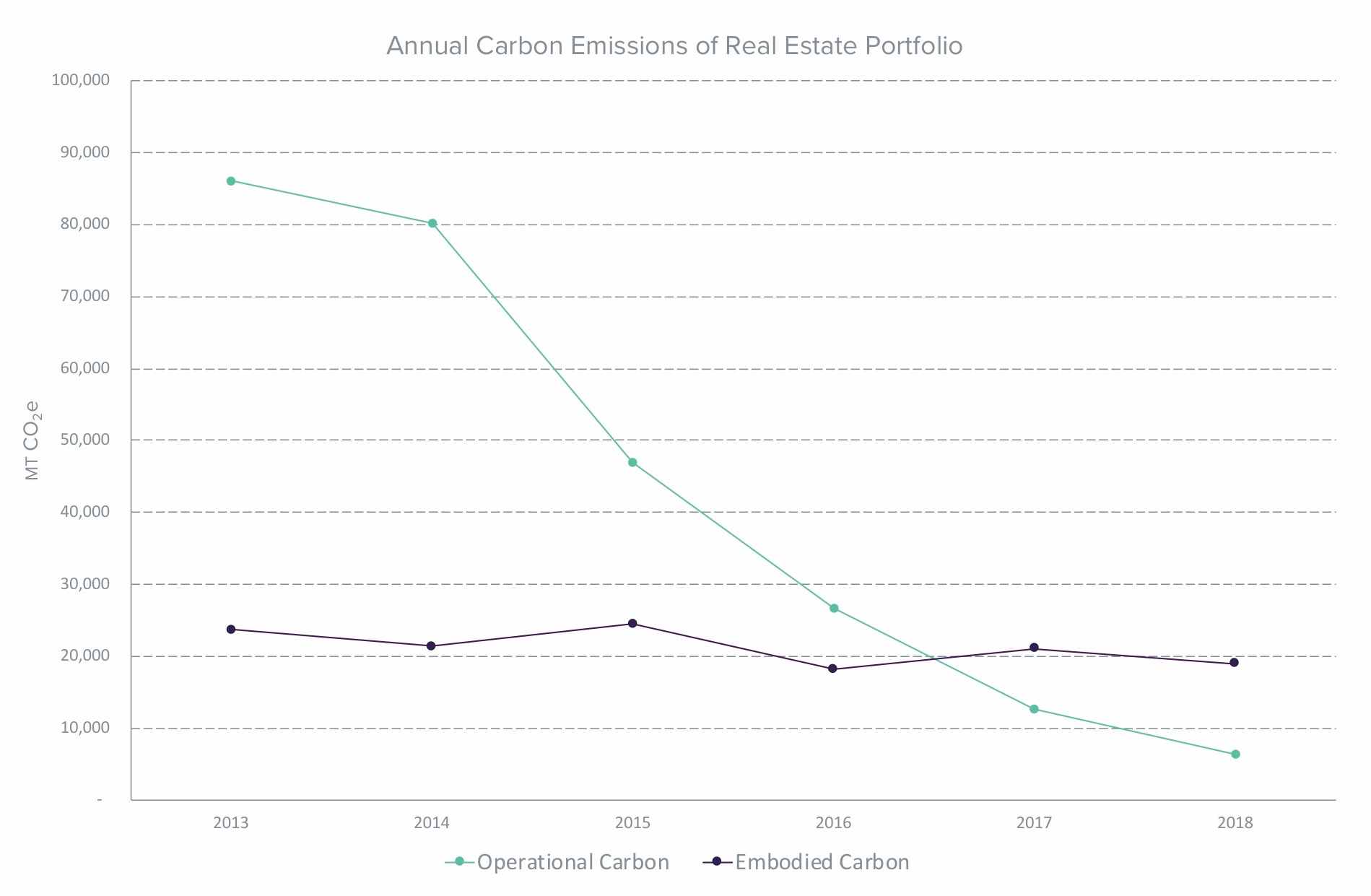

Embodied carbon analysis does not have to be confined to a single building. Much like how firms perform robust carbon accounting of operational emissions (building energy use), transportation emissions, and emissions associated with their products, firms can and should account for another important piece of their footprint: the embodied carbon of their building fleet. By applying embodied carbon analysis to whole portfolios through an LCA consultant, companies can truly start to understand and reduce their entire carbon footprint. This is important because as firms are investing more and more in renewables, embodied carbon is becoming the primary carbon emitter of real estate portfolios.

Design Standards:

Many organizations have developed standards that are used as a basis for all future space design. Performing embodied carbon analyses on these design standards can have significant impacts, as individual changes impact all future real estate owned or occupied by the company. Additionally, this approach presents an opportunity to integrate carbon into space programming and cost models, influencing decisions in the early planning stage.

WHAT MATERIALS SHOULD BE INCLUDED IN MY LCA?

Historically, embodied carbon analysis has been focused on a building’s structure and enclosure. However, increased market demand, improved data, and streamlined tools have now made it possible to analyze a variety of project types, as mentioned above.

Putting the “Whole” in Whole Building LCA:

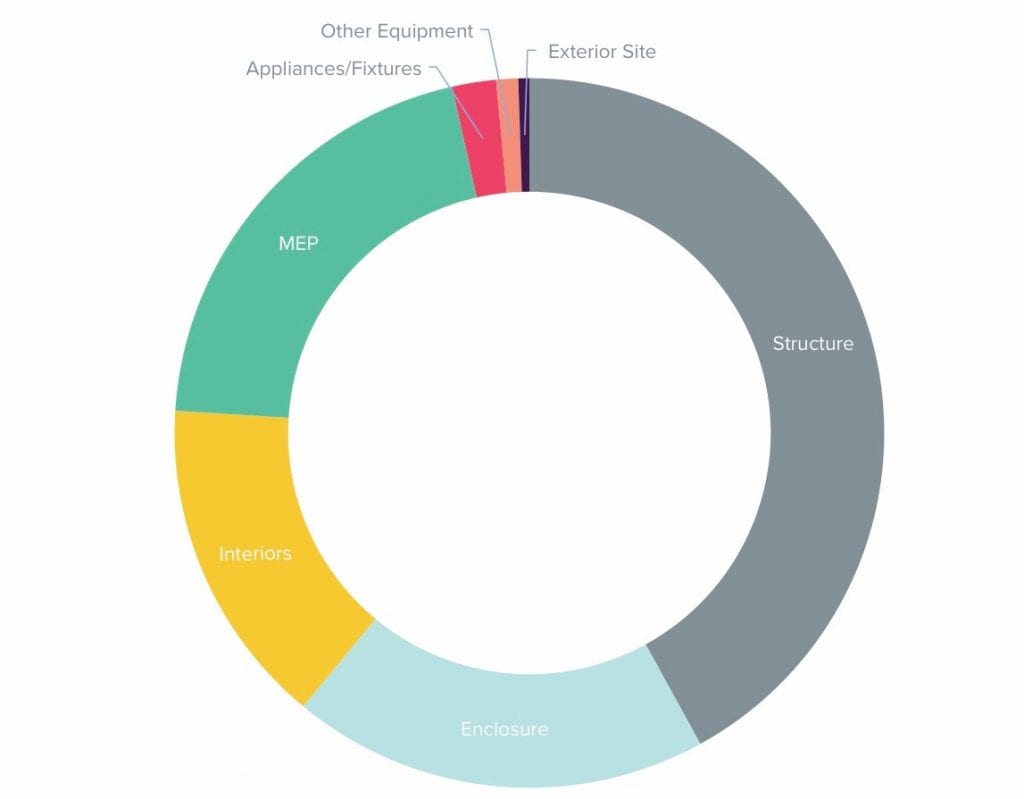

LEED v4 for New Construction includes a credit that grants points for performing a Whole Building LCA, which quantifies embodied carbon and other environmental impacts. Despite the name, only the structure and enclosure of the buildings are required to be analyzed. We recommend including additional building systems in the analysis to truly understand and reduce the environmental impacts of the whole building. See below for a typical breakdown of embodied carbon material impacts by building system:

Source: Simonen, K. (2015) “Testing Whole Building LCA: Research and Practice”

WHEN SHOULD I INVOLVE AN LCA CONSULTANT?

In a word, anytime! Involving an LCA consultant at the earliest stage of the process is the best and easiest way to make sure you’re addressing your carbon footprint throughout a building’s full life cycle. While the earlier the better, it’s still encouraged to involve an LCA consultant at any project stage. See why in the breakdown below:

Prior to Design:

There is value in engaging an LCA consultant very early in the process to brief the team on approaches to Low Carbon Design. There is huge (and currently untapped) potential for real estate to be a net carbon sink – a solution to, rather than cause of, climate change – if certain considerations are made early in the process, even before early design begins.

Early Design:

Once an initial design has been developed, an LCA can be performed to understand embodied carbon “hot spots” (materials and processes that are most responsible for a building’s embodied carbon emissions) as well as opportunities for improvement. If designs for certain systems are not fully fleshed out, the LCA consultant can compare idealized system options to provide direction to the team.

Final Design:

Involving an LCA consultant later in the design process can still help reduce a project’s embodied carbon. At this later stage, the results from an LCA can help drive decisions to reduce carbon through material substitutions rather than design changes. For example, steel with a certain recycled content or a specific brand of gypsum board may be recommended.

Construction Administration:

Occasionally, the General Contractor may propose products that differ from the design. GCs typically do not consider embodied carbon, so it’s important to engage an LCA consultant to vet product substitutions to ensure alignment with carbon reduction goals.

Project Completion:

As was the case with DPR Construction and Stok’s Net Zero Energy office in San Francisco, projects occasionally do not analyze embodied carbon until after construction is complete. In DPR and Stok’s case, it was shown that adaptive reuse led to a whopping 70% embodied carbon reduction. Projects can analyze embodied carbon after completion to understand total impacts, seek areas for improvement, and influence future design.

WHAT RESULTS CAN I EXPECT AND HOW CAN I USE THEM?

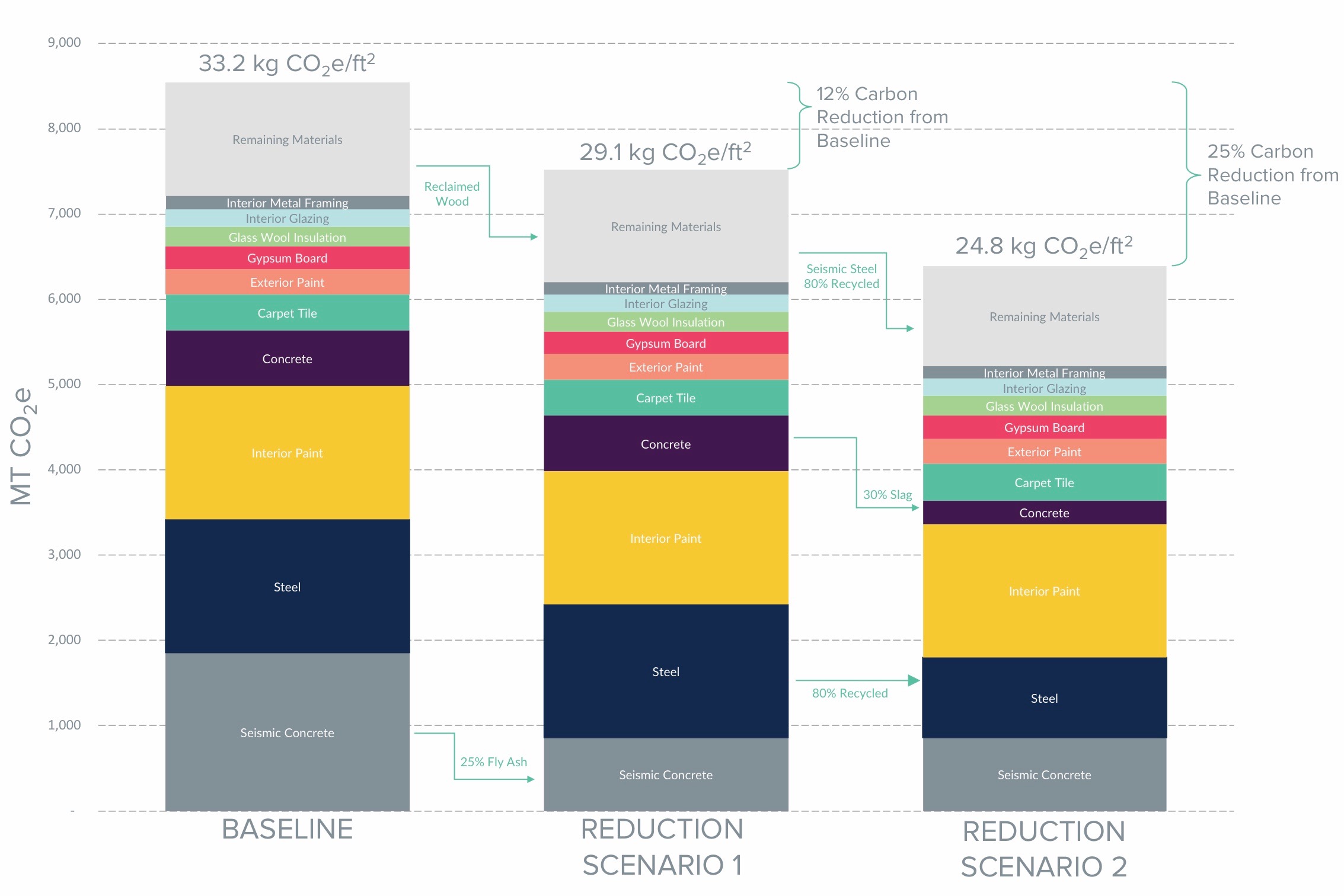

An embodied carbon analysis provides project teams with an outline of your project’s carbon intensity as well as recommendations for how to most effectively reduce or eliminate embodied carbon on your project. Specifically, Stok’s embodied carbon analysis provides:

• An individual breakdown of the embodied carbon of top 10 materials, plus remaining materials

• The total carbon intensity (kg CO2e/ft2) of your project’s materials at baseline

• Specific recommendations for 2 embodied carbon reduction scenarios

• The overall carbon reduction for the 2 scenarios compared to baseline

Here’s an example of a resulting embodied carbon analysis, which can be used by a project team to determine the best carbon reduction strategies for a project that align with other project goals, optimize design, and reduce overall carbon footprint:

If you’re interested in reducing embodied carbon on your project, get in touch with Stok’s LCA consultants!