With commercial and public buildings largely unoccupied amid stay at home orders across the country, virtual building control capabilities are being put to the test. Saving on energy costs is only more important during this health and economic crisis, and sound energy management can make a big difference on operating costs.

Here we take a live look at building data to explore what we’ve learned so far about energy management during COVID-19 and begin to think about what we need to do from an energy perspective to prepare for future disruptions.

ENERGY MANAGEMENT MUST-HAVES

So far, the two most important energy management capabilities during the COVID-19 crisis are:

#1: Remote Building Controls

It was immediately apparent that the ability to control a building remotely is critical. This capability gives owners access to adjust schedules and setpoints in empty buildings, thereby reducing loads that would otherwise be wasted on an unoccupied building. Centralized/ remote control means facilities personnel don’t need to physically be on site to make adjustments. HVAC and lighting controls can be integrated into a centralized building automation system. In new construction this strategy should be included during the early design phase, but these features can also be added to existing buildings.

#2: Granular Energy-Use Data

The ability to see granular end-use data is also key. This helps identify what loads are operating in an empty building that shouldn’t be. Without granularity, owners aren’t able to pinpoint issues and identify where changes are necessary, which can lead to missed energy and cost savings. End-use data can be obtained through submetering that can be installed in both new construction and existing buildings. Integrating those submeters into a centralized building automation system or a third-party, cloud-based system allows for remote monitoring.

WHAT DOES THIS LOOK LIKE IN PRACTICE?

Now let’s dive into some real energy data from a building operating during COVID-19.

The 12,000 square foot public library building below has end-use submeters installed and integrated into the central building automation system. This allows the owner to monitor the energy use in real time and adjust schedules remotely. Located in San Diego, the building was monitored before and after California’s stay at home orders went into place and has displayed significant energy use reduction due to automatic controls and remote scheduling capabilities.

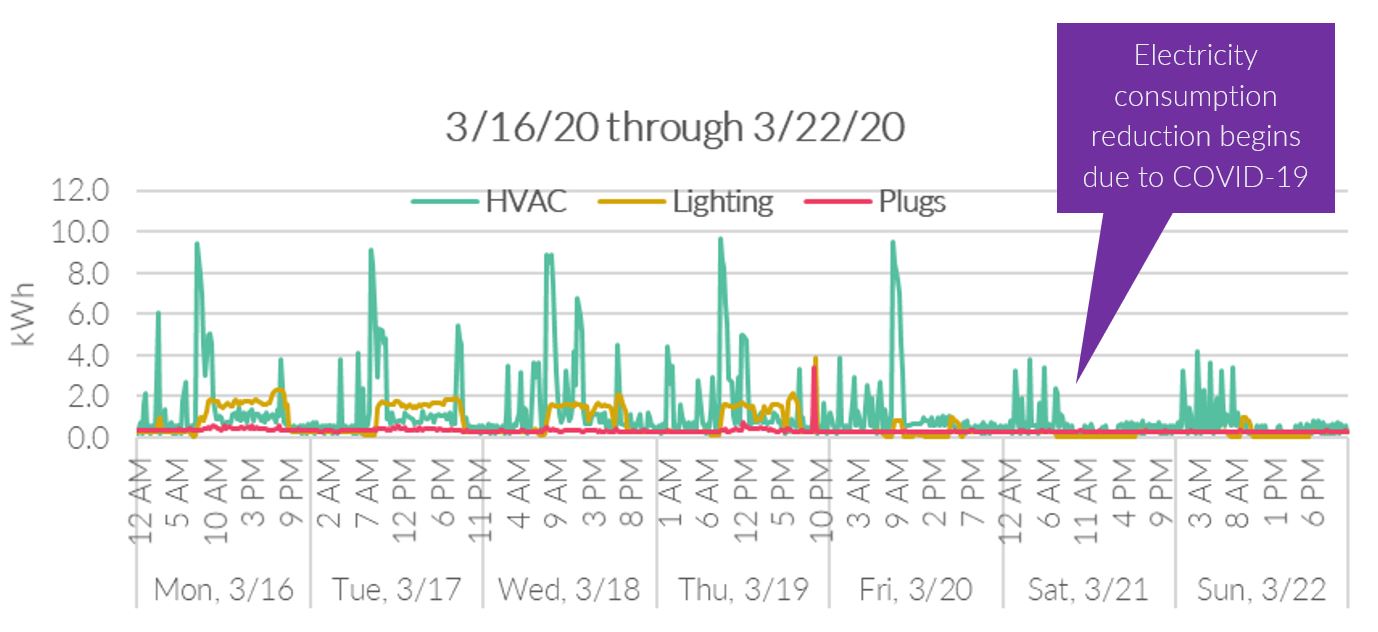

The chart below illustrates initial energy reductions due to local automatic controls:

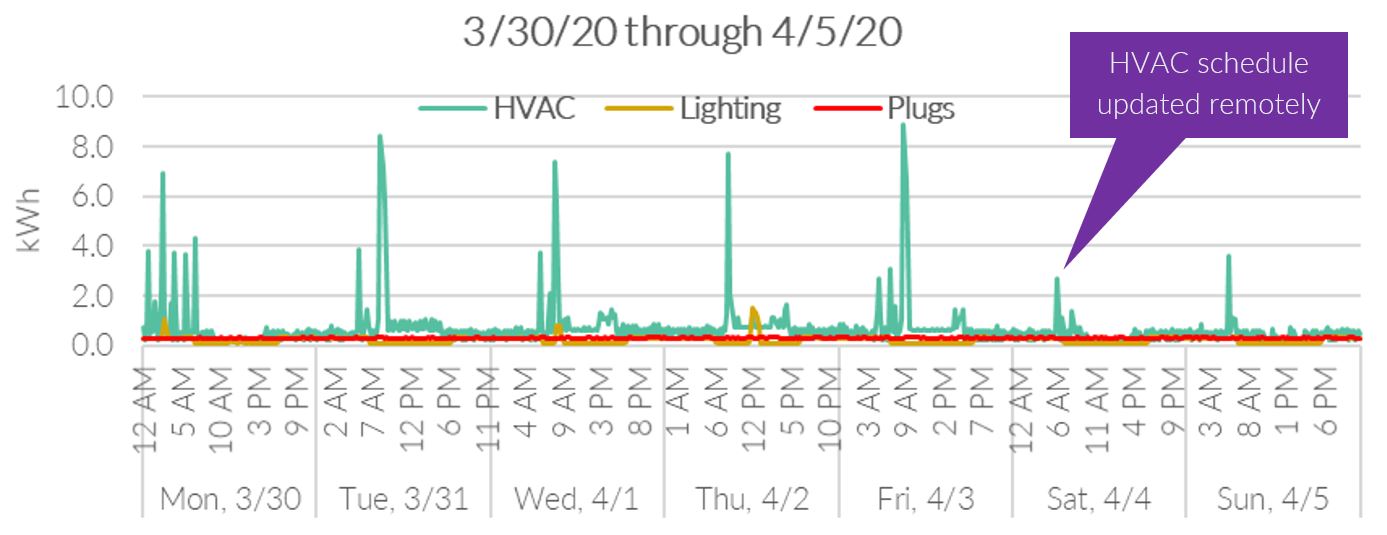

The owner is very conscientious about energy use and is able to review real-time, end-use submetering data in their remote Building Automation System Dashboard. Once they noticed the continued operation of the HVAC system in an empty building, the schedules and setpoints could be changed remotely. We can also confirm that the building’s automatic lighting controls are operating properly, resulting in additional energy use reduction:

The data tells a story—without the real-time data the owner would not know what equipment or systems are operating when they shouldn’t be. We can see where electricity consumption begins to drop, thanks to the detailed data on loads and the capability to operate the building remotely. The HVAC scheduling was revised, allowing the building owner to optimize energy and cost savings, which are even more important in this time of crisis.

WHAT ELSE CAN WE LEARN FROM ENERGY MANAGEMENT DURING COVID-19?

These are our early takeaways from energy management during the COVID-19 pandemic. Owners and energy analysts alike should be asking more questions, including:

1. What worked and what didn’t when we turned off our empty commercial and public buildings?

2. Which buildings saved energy and which didn’t—and why?

3. What are key trends in residential energy use and how do they compare to commercial energy use?

4. How can we be more resilient to prepare for future disruptions?

5. How can we take lessons learned from this experience and incorporate them into the projects we are currently designing?

Reach out to our engineers to discuss further.