First came operational carbon, then embodied, and now? Whole life carbon. While the green building industry has begun to put much needed focus on both operational carbon (energy used throughout a building’s life) and embodied carbon (building materials’ lifecycle carbon emissions, from extraction, manufacturing, and transportation, to end of life), it’s now time to combine the two topics for better, more effective modeling and powerful decarbonization results.

LINKED, YET SILOED

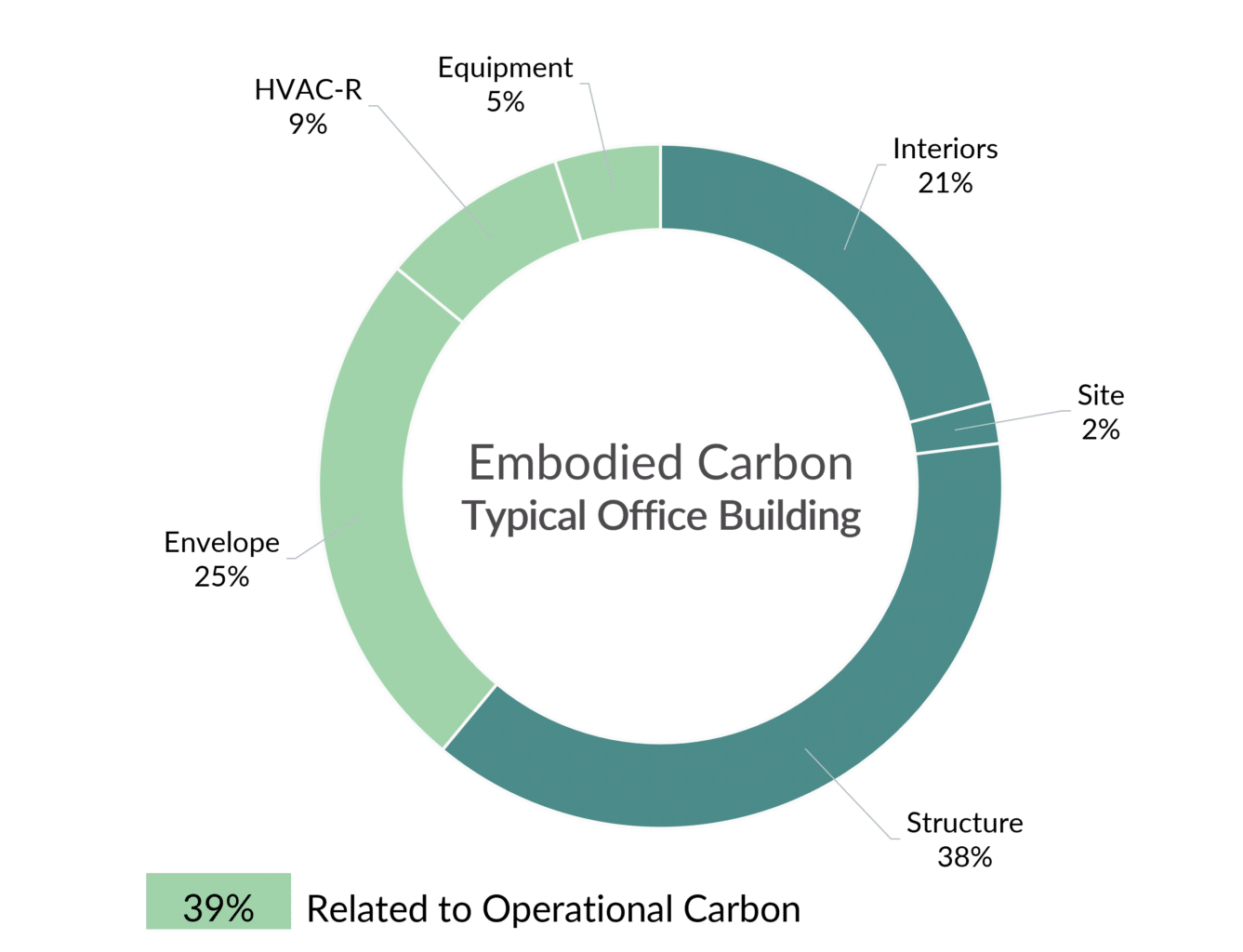

The graphic below shows embodied carbon hot spots in office building projects, of which nearly 40% also impact the building’s operational carbon, including envelope, HVAC, and equipment.

Typical office building’s embodied carbon, showing linkage to operational carbon.

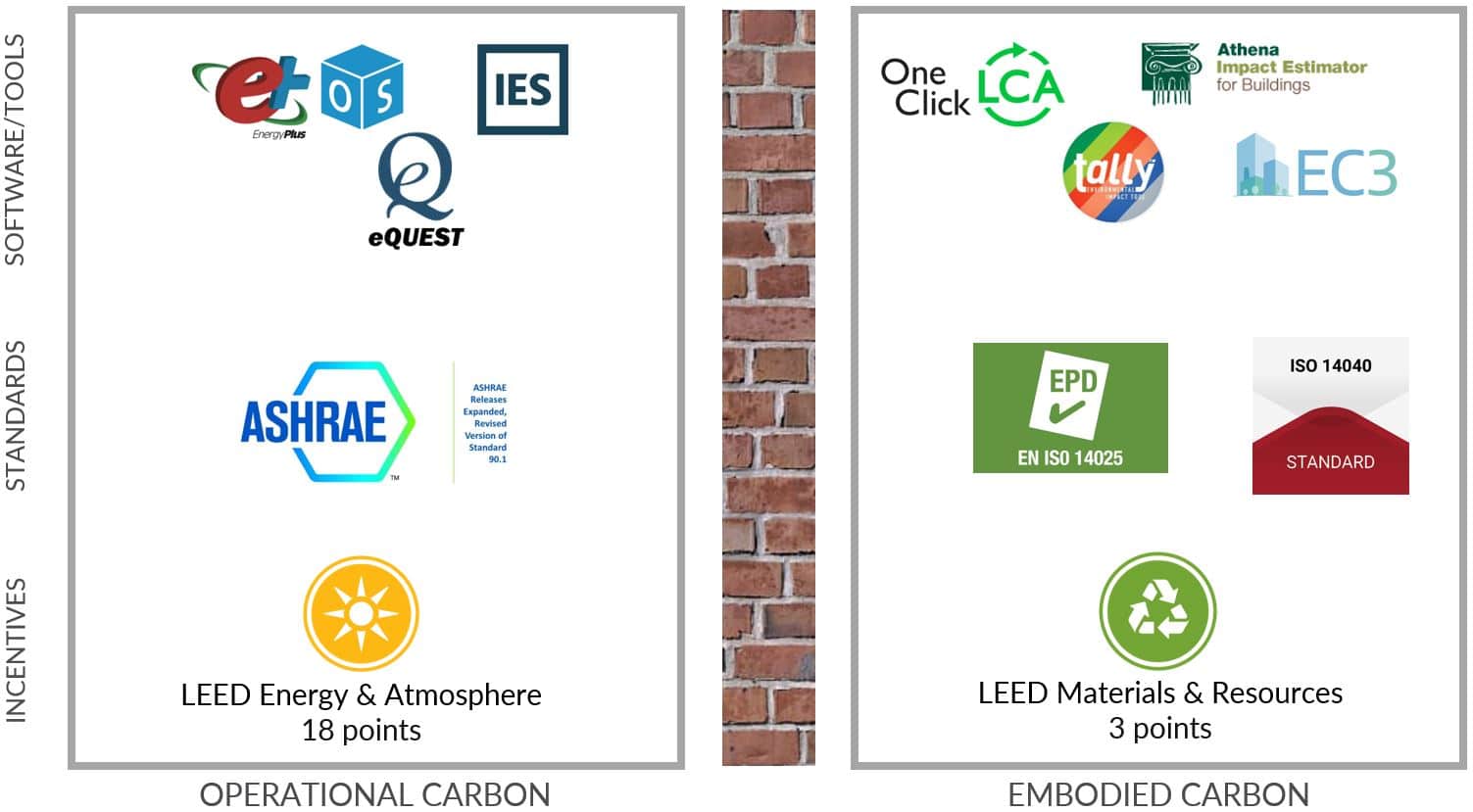

Despite this link, operational carbon and embodied carbon live in two silos. From the software that’s used for modeling, to the applicable standards, all the way to the incentive programs that are available for reduction, these two concepts currently occupy separate worlds.

INTRODUCING WHOLE LIFE CARBON

So, what do we need to do to take a step forward and holistically look at these two concepts together? Combining operational carbon and embodied carbon analysis into whole life carbon will allow project teams to make much better holistic design decisions. This is possible by combining life cycle assessment (LCA), which is used to quantify embodied carbon, with energy modeling, used to model operational carbon. As RICS puts it, this whole life carbon approach “identifies the overall best combined opportunities for reducing lifetime emissions, and also helps to avoid any unintended consequences of focusing on operational emissions alone.”

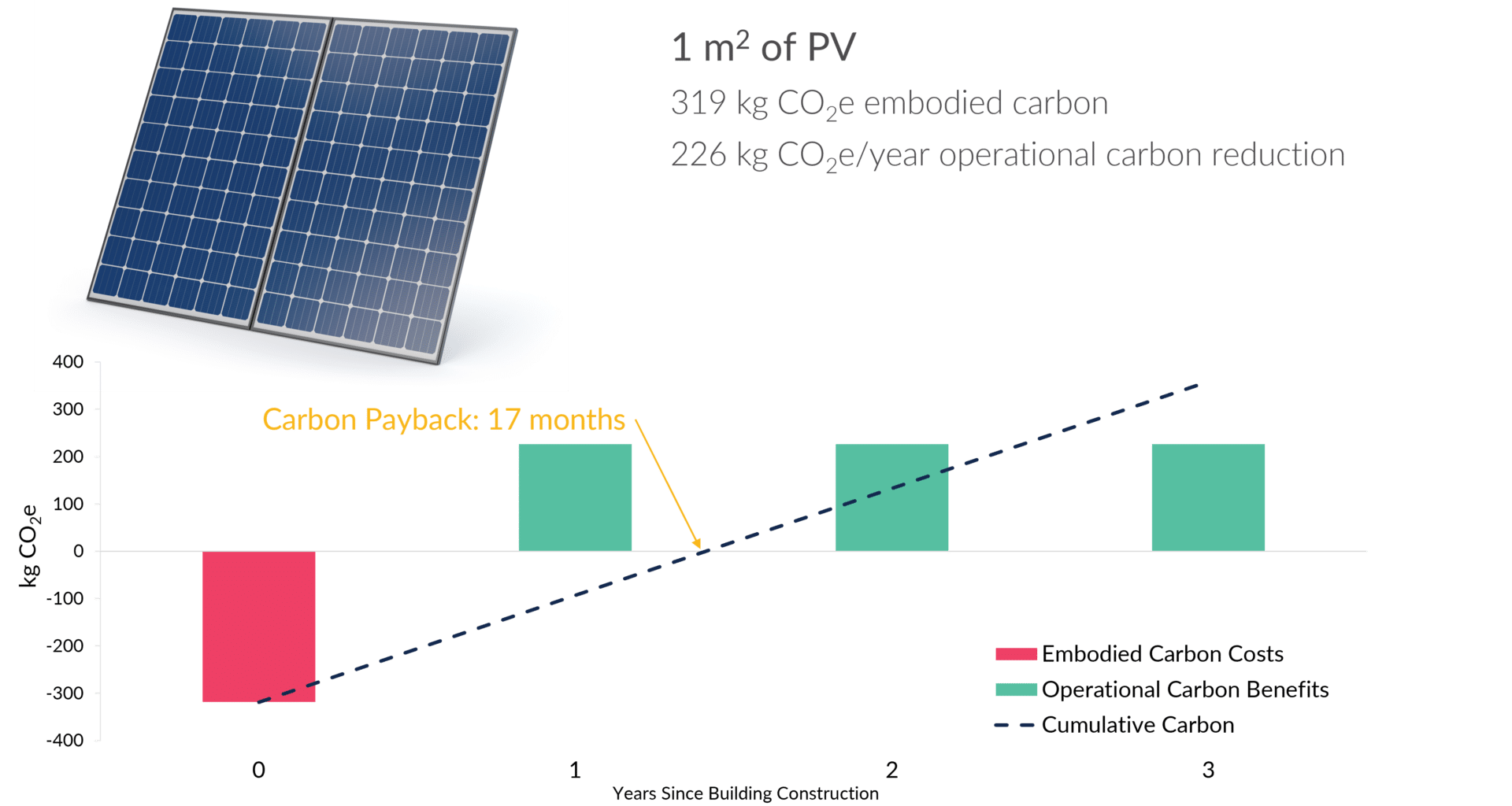

Let’s put this concept into practice:

If you’re analyzing the embodied carbon of 1m2 of PV, you can see its embodied carbon costs (pink column below) as well as the operational carbon reduction (teal columns below) over time that the PV panel contributes to once the building’s online. With whole life carbon modeling, we can calculate a carbon payback that shows how long that initial investment in embodied carbon takes to pay back. In this example, it’s about 17 months, which is a relatively quick payback period and a smart investment from a financial and climate perspective.

Payback period of 1 m2 of PV when holistically considering embodied carbon costs and operational carbon benefits.

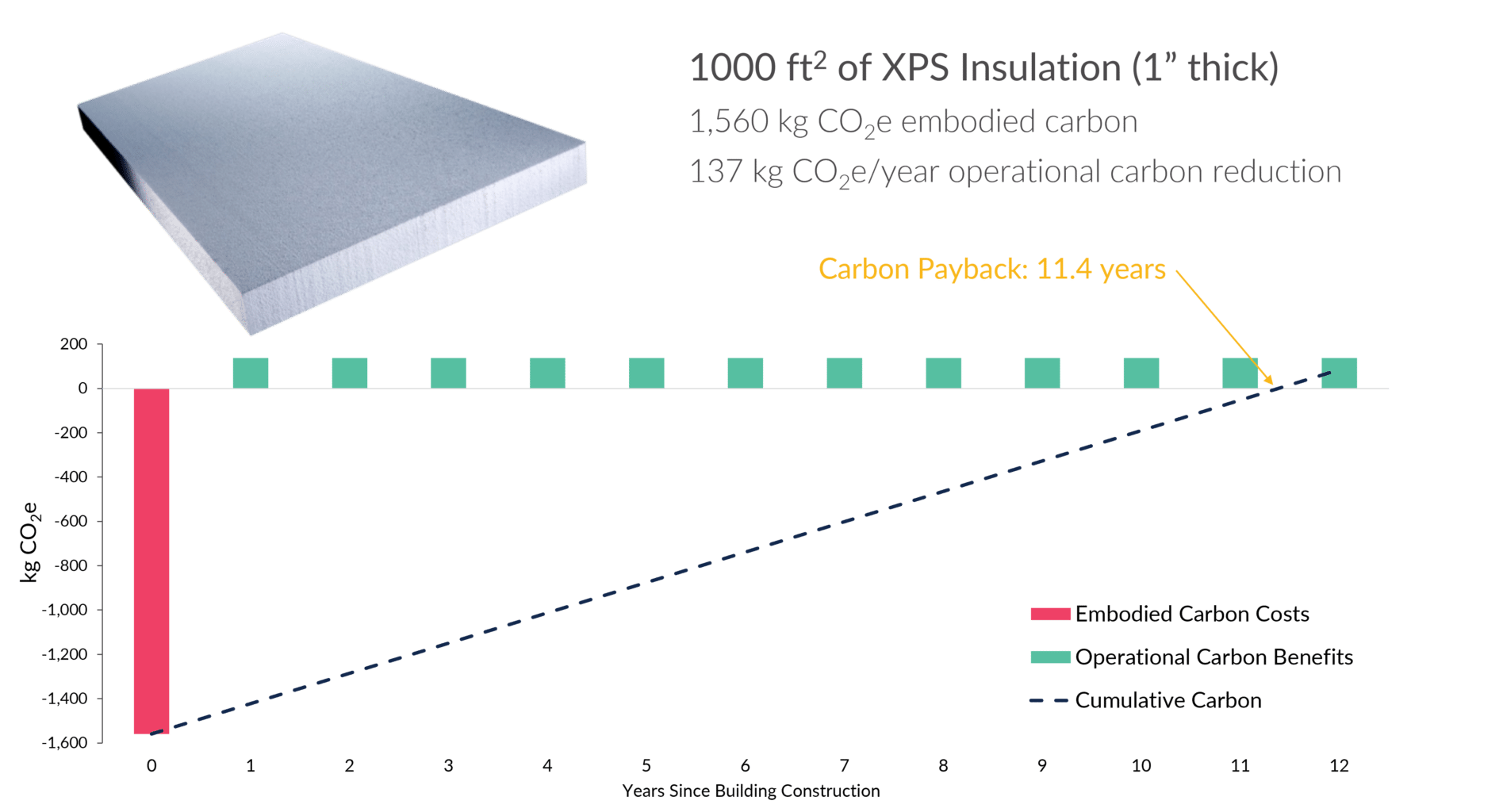

A different example looking at 1000 SF of insulation shows a much higher embodied carbon cost (pink column below) and lower operational carbon benefit (teal columns below), resulting in a payback period of 11.4 years. Given the much longer payback period and scientists’ urgent call to curb climate impacts before 2030, this investment may cause hesitation and prompt the project team to uncover other areas for more rapid payback.

Payback period of 1000 SF of XPS insulation when holistically considering embodied carbon costs and operational carbon benefits.

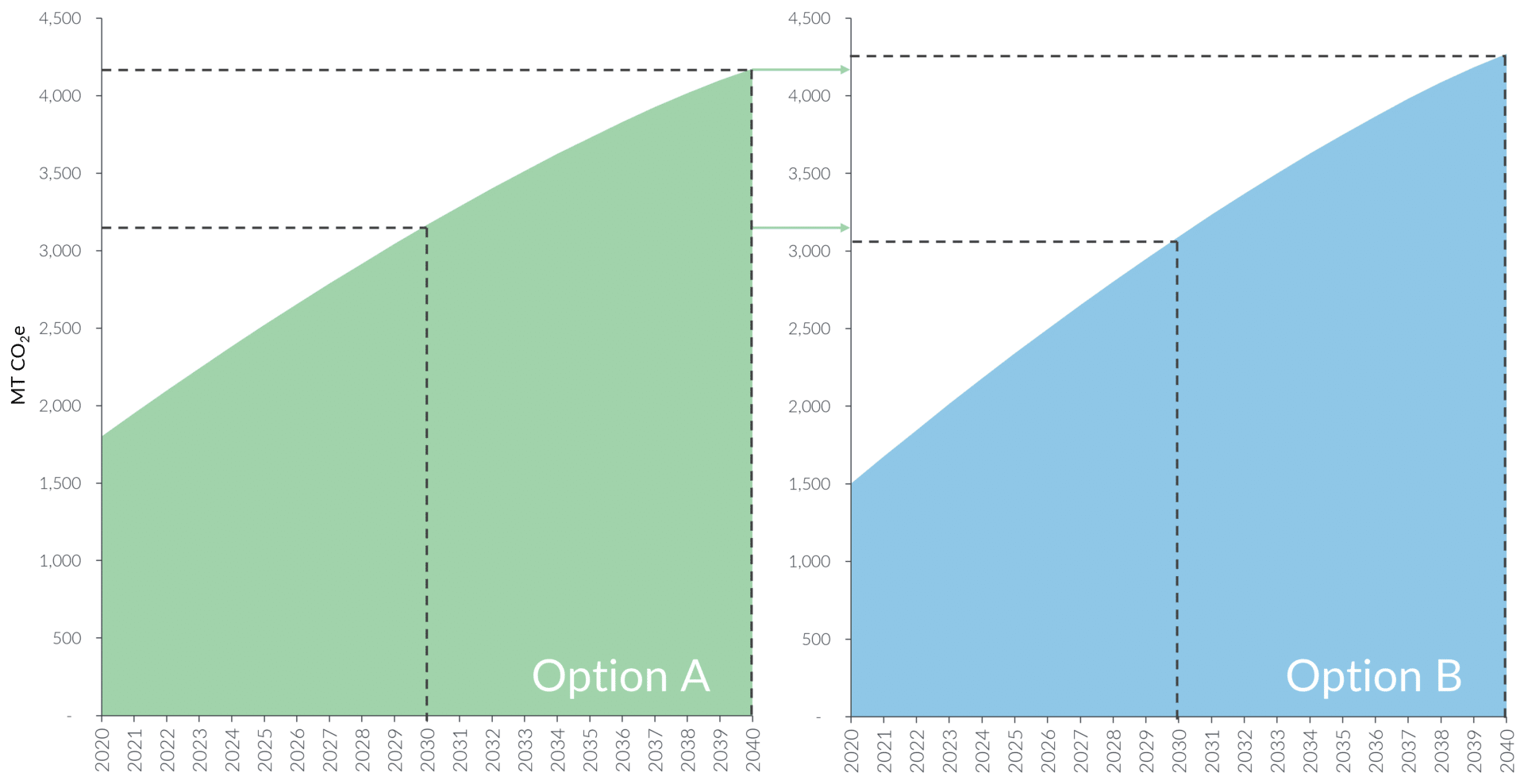

We can stretch this concept out to entire buildings too. Below is the carbon profile of two design options of the same building showing cumulative carbon over the next 20 years. By looking at a single building over time, we can also quantify the impacts of more renewables being added to the electric grid. Through whole life carbon modeling, we can look at single places in time (like 10 or 20 years into the building’s life) and compare what we’re doing to make holistic carbon decisions. In the example below, Option A results in more carbon emissions over the first 10 years, but less over 20 (and likely beyond). In this case, the decision would have to be made by looking at emissions for the building’s entire lifespan.

SO, WHAT CAN YOU DO?

Breaking down the operational and embodied carbon silos is critical to rapidly driving toward a decarbonized future. The first practical step you can take to move whole life carbon forward is to coordinate with the energy modelers and LCA practitioners on your project team to connect these concepts and ensure you’re looking at both sides of the equation when making design decisions. We recommend initiating this collaborative approach early in the design process, though there are still benefits to engaging later in the project schedule.

Learn about more ways to realize low embodied carbon design in Carbon Leadership Forum’s 3 Minutes of Brilliance pitch series and reach out to our team to further discuss decarbonization targets and strategies.

Hero image: One De Haro

Rendering: Steelblue

Design: Perkins&Will